Most arc flash studies follow a predictable path. Collect field data, build the model, run the calculations, print the labels. If everything checks out, you move on.

But sometimes the calculations reveal problems that have nothing to do with incident energy. During a recent study at a manufacturing facility in Minnesota, I found three separate NEC violations that had been there since the equipment was installed. None of them were obvious. All of them required digging into manufacturer data and cross-referencing it against actual fault current calculations.

Here’s what I found.

1. Series Combination Ratings That Don’t Add Up

This facility uses Eaton Power Defense PDG3 breakers (M-tier, 65 kAIC at 480V) as feeder breakers protecting downstream panels. The branch breakers in those panels are Eaton GHB frames, which have a standalone interrupting rating of just 14 kAIC at 480V.

Eaton Power Defense PDG3_M, 400A feeder breaker. Catalog: PDG33M0400FNNN

That’s fine on its own. The whole point of a series combination rating is that the upstream breaker helps the downstream breaker interrupt faults beyond its standalone capacity. The two breakers are UL-tested together, and the combination gets a higher rating than the branch breaker alone.

But here’s the catch most people miss: series combination ratings aren’t blanket numbers. They vary by the ampere size of the downstream breaker, even within the same breaker family.

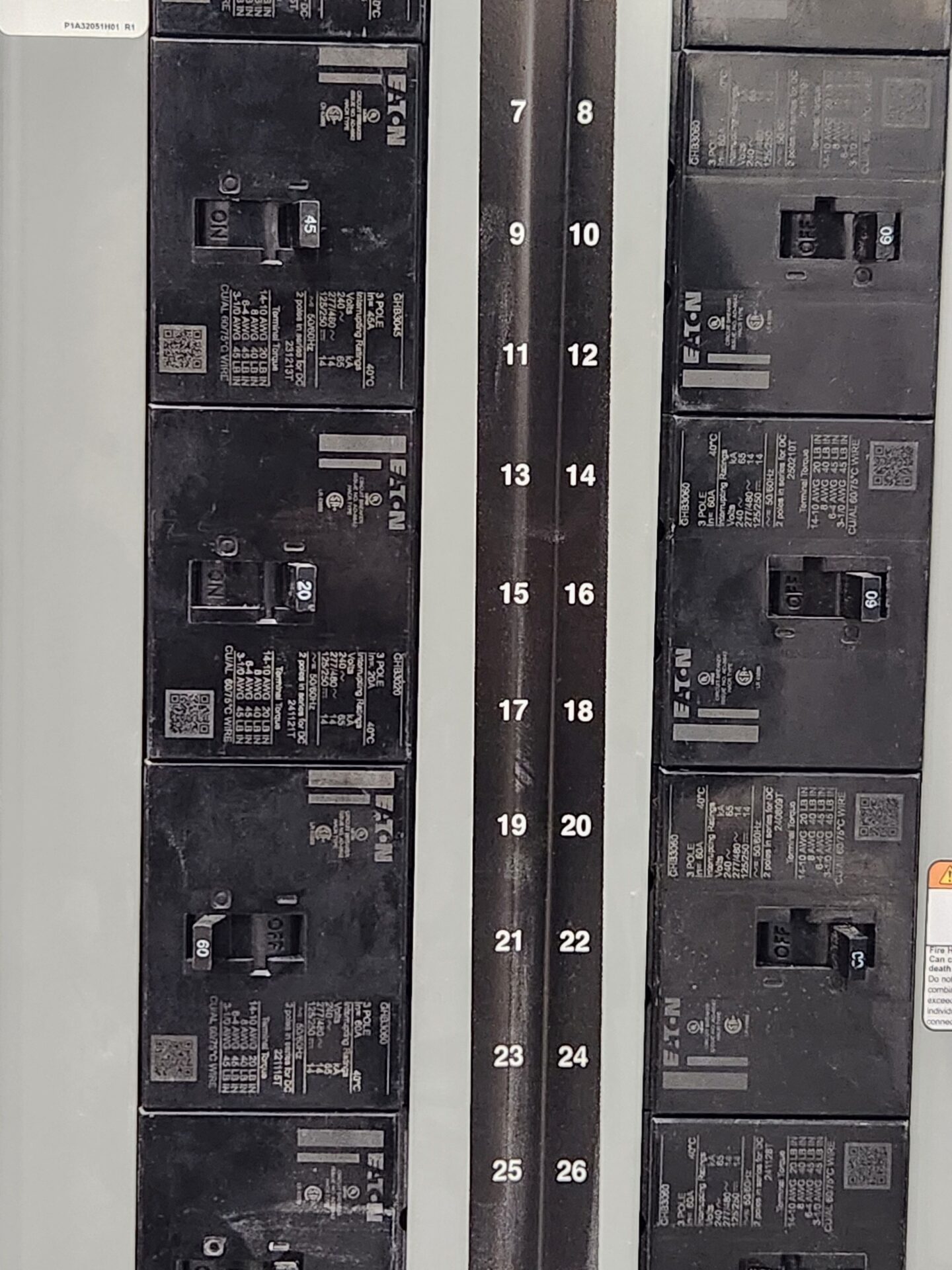

Eaton GHB 60A branch breaker. Standalone rating: 14 kAIC at 480V

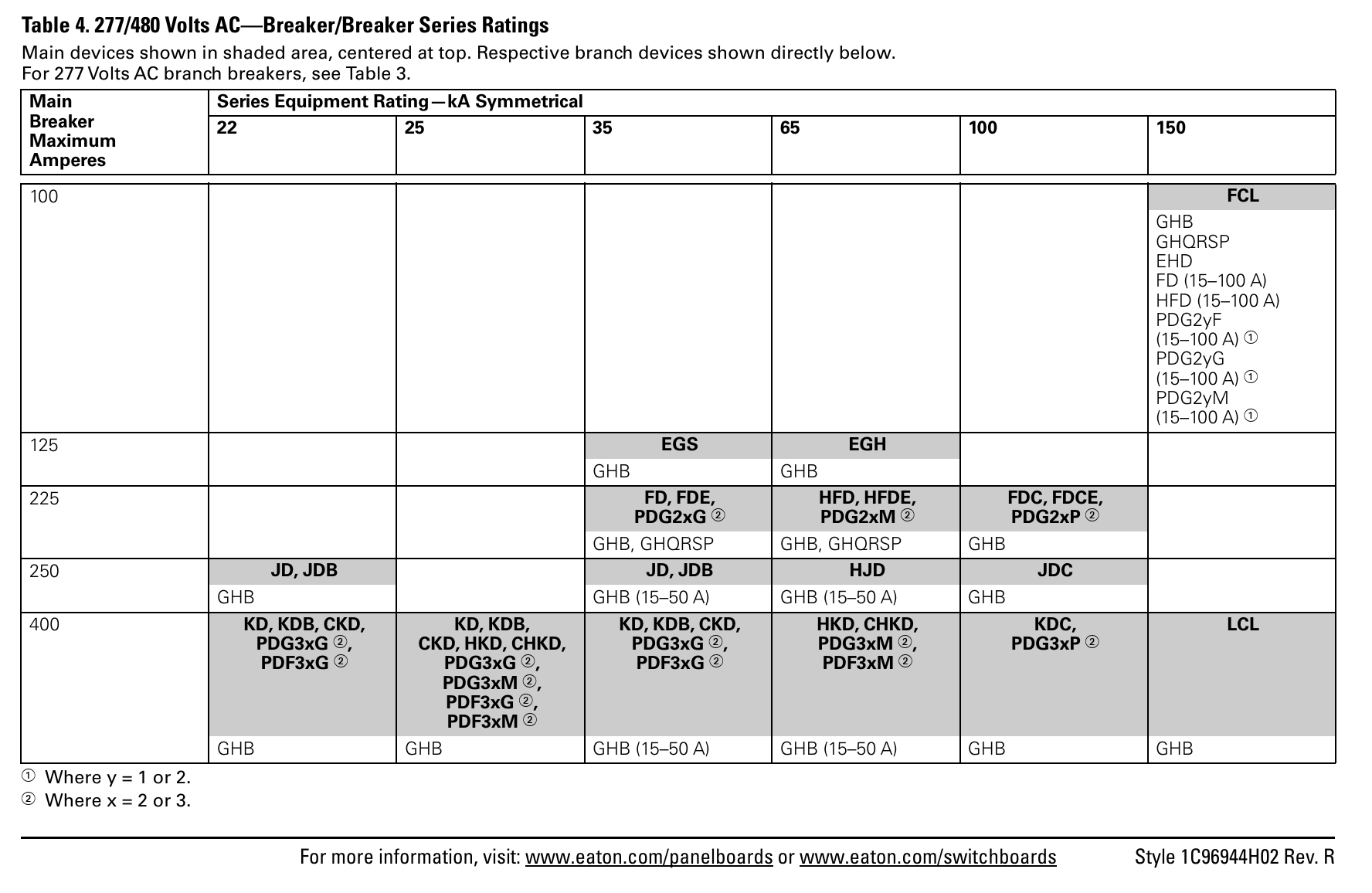

Per Eaton’s series rating publication (1C96944H02, Table 4), the PDG3_M at 400A upstream with GHB downstream at 277/480V gives you:

Eaton Publication 1C96944H02, Table 4. Note the 400A row: PDG3xM appears in the 25 kA and 65 kA columns with different GHB amp restrictions

The available fault currents at the two problem panels were 29.6 kA and 39.8 kA. Every GHB breaker rated 60A and above at those locations was inadequately rated per NEC 110.9. That’s ten breakers across two panels.

The fix is straightforward. Either replace the ten branch breakers with higher-rated units, or swap the two upstream feeder breakers to the PDG3_P (current-limiting tier), which provides a 100 kA series combination rating with all GHB sizes. Two breakers instead of ten.

2. Wrong Voltage Rating on a Breaker

One panel had an Eaton Power Defense PDG2_M breaker rated for 240V installed in a 480V system. The breaker physically fits the panel. Same frame, same mounting. But its interrupting rating and voltage class are only listed for 240V.

This is a straight NEC 110.9 and 110.3(B) violation. A breaker must be rated for the voltage of the system it’s installed in. The 240V breaker needs to be replaced with the 480V-rated version of the same frame.

How does this happen? Usually during a replacement or panel upgrade, someone orders the wrong catalog number. The breaker looks identical, installs the same way, and functions normally under everyday load. It’s only a problem when a fault occurs and the breaker needs to interrupt current at a voltage it was never tested for.

3. Transfer Switch Breakers Not on the Approved List

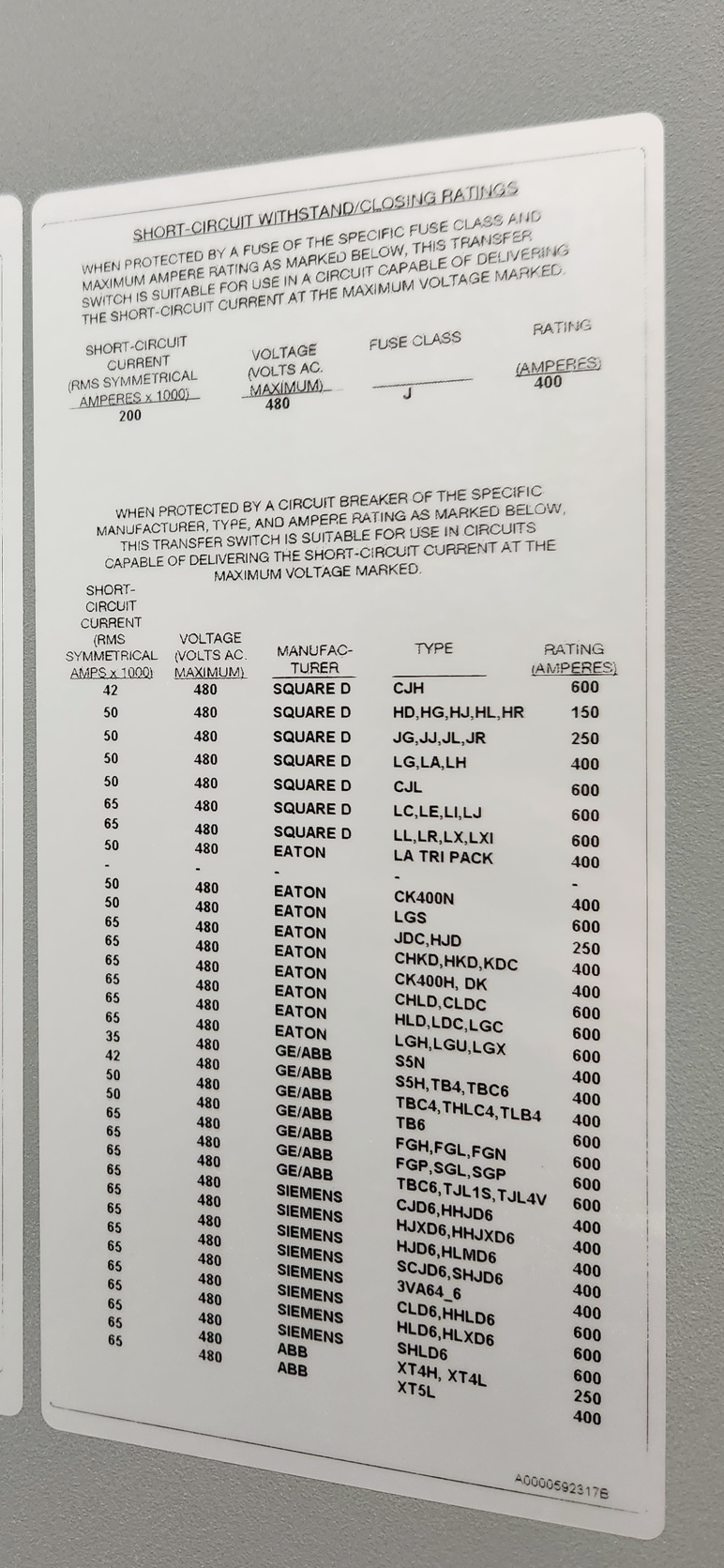

The facility has a Generac automatic transfer switch (ATS) with a standalone short-circuit withstand rating of 35 kA at 480V. The available fault current at that location is 36.6 kA, which means the ATS exceeds its standalone rating and relies on a series combination with the upstream breaker for adequate protection.

Generac ATS nameplate showing approved breaker combinations. Note: only legacy Eaton Series C breakers are listed.

The problem is the installed upstream breakers are Eaton Power Defense PDG3 units, and those breakers aren’t listed on the Generac ATS nameplate. The nameplate only references legacy Eaton Series C breakers (HKD, CHKD, KDC, etc.) that the Power Defense line replaced.

The Power Defense PDG3 is the functional replacement for the Series C line, and it carries the same interrupting ratings. But UL series combination ratings are specific to the exact breaker models that were tested together. Functionally equivalent doesn’t mean UL-tested equivalent.

Until Generac confirms the Power Defense breakers have been added to their UL combination testing, the ATS withstand rating at this location is unverified.

Why This Matters

Three different issues. Three different code sections. One common thread: they all required actually modeling the system, calculating fault currents at each bus, and cross-referencing manufacturer data against field conditions.

A label-only arc flash vendor wouldn’t catch any of these. They’d slap labels on the panels and move on. The labels might even be technically correct for incident energy, but the equipment behind those labels wouldn’t be code-compliant.

This is what a comprehensive arc flash study actually looks like. It’s not just about PPE categories and boundaries. It’s a full audit of your electrical system’s ability to safely handle the fault currents available to it.

Is Your Facility Due for a Study?

If your facility hasn’t had a comprehensive arc flash study, or if the last one was just labels without a full short-circuit and protective device analysis, you might have similar issues hiding in your panels.

Visit us at zechengineers.com/contact. We’ll give you a straight answer on what your facility needs.